Developing sustainable products

Thorlux is an enabler in the global transition to a low-carbon economy through the products it manufactures and sells. The company's approach has always been to provide highly efficient, long-lasting and reliable luminaires that can be easily maintained and serviced.

Product efficiency and optical control of light are vital, and when combined with the SmartScan lighting management system, they ensure the objective of 'right light, in the right place, at the right time' is achieved, helping our customers reduce their through-life costs and carbon emissions.

The circular economy and the reduction of embodied carbon are key pillars in the specification and development of new products.

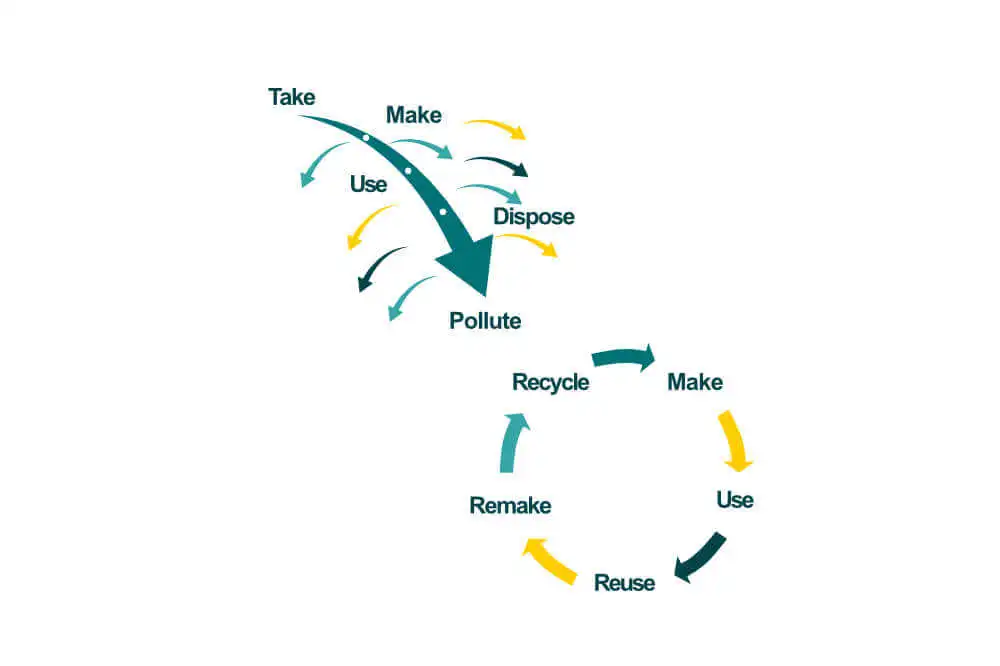

What is the circular economy?

Principles of the circular economy

Every item bought or sold comes from raw materials extracted from the Earth; manufacturers turn these materials into products, and eventually, they are discarded as waste. This linear process drains the planet's finite resources while generating significant waste and emissions.

An alternative model is to become less linear and more circular. This means considering a product’s lifetime and maintainability as well as the possibility to reuse, refurbish or even remanufacture once the product’s initial use comes to an end. This circular approach captures and keeps materials in use at their highest value. This idea has been evolving since the 1980s; it aims to minimise waste and pollution by optimising the value and use of resources.

The linear approach of creation, consumption, and disposal is not sustainable. Circularity is a strategy to increase sustainability, reduce waste and maximise the reuse of materials.

Our approach to the circular economy

Thorlux is committed to designing and manufacturing sustainable products that incorporate circular economy principles. To guide our design process, Thorlux uses the TM66 circular economy framework issued by the Chartered Institution of Building Services Engineers (CIBSE) and the Society of Light and Lighting (SLL).

What is TM66?

TM66 is an exacting framework that demands proof of the highest standards from lighting product designers and manufacturers. It provides guidance on how to asses the circularity of a luminaire, including “a checklist, method of assessing a product's circular economy performance, and real-world examples of good practice.”

The TM66 framework is now an integral part of new product development for Thorlux, focused on long life, efficiency, and reusability as essential product requirements. Thorlux has set a standard stating that all new products must achieve a minimum TM66 score of 2.5 (excellent circularity).

Making the most of materials

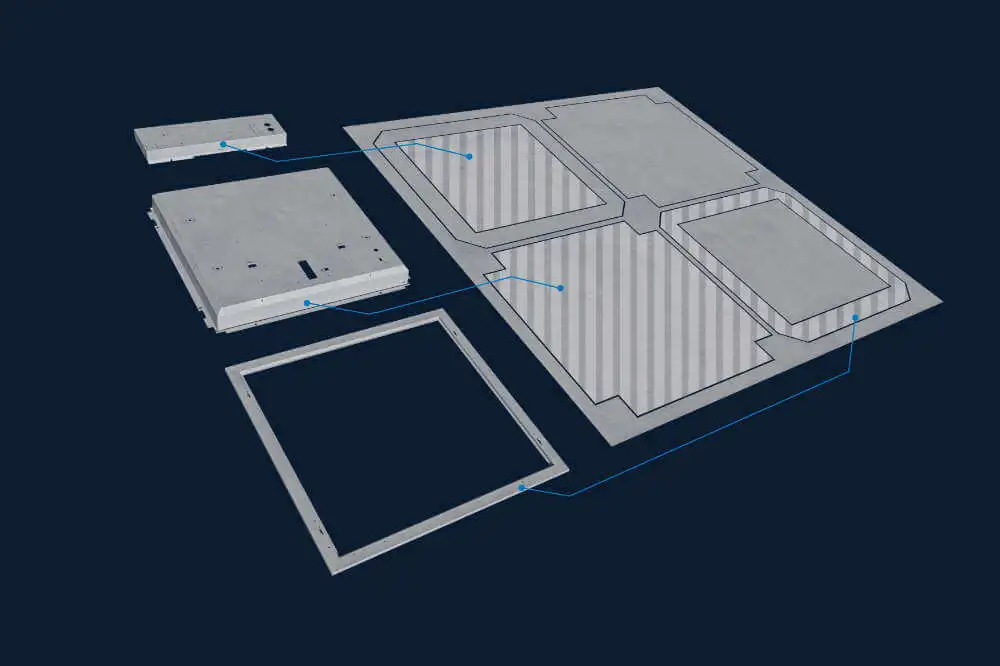

Maximising material utilisation is crucial for achieving circular economy goals, including eliminating waste wherever possible. Thorlux considers this in every stage of its process, from luminaire design and development through to manufacturing.

Thorlux selects the materials used in its luminaires with sustainability in mind. For example, sheet steel is ideal for providing a long and reliable lifetime and is fully recyclable. Thorlux uses a wide variety of different materials selected to meet product and application criteria. In all cases consideration is given to the environmental impact at creation, the recycled content, selecting highest grades of recycled content where possible and the ability to recycle once end of life is reached. Further consideration is given to minimising waste. For example, during the design phase by selecting a suitably sized sheet of steel and optimising the component layout to maximise utilisation. Often, 'waste' cutout material is used to manufacture accompanying components, with cuttings nested one within the other. This utilises as much of the material as possible.

What is embodied carbon?

Embodied carbon refers to the total amount of greenhouse gas emissions associated with the production, transportation, and disposal of materials used in the construction, manufacturing, or operation of a product, building, or infrastructure over its entire life cycle. This includes emissions from processes such as raw material extraction, manufacturing, transportation, construction, maintenance, and end-of-life disposal.

Measured in kg CO₂e of GWP (kg of carbon dioxide equivalent of global warming potential), around 1 in 10 tonnes of the UK’s total greenhouse gas emissions are so-called “embodied carbon” emissions, related to the production and use of construction materials. They total 64 million tonnes CO₂e per year, more than the country’s aviation and shipping emissions combined.

Embodied Carbon can account for up to 40% of the total GHG emissions generated in a building’s lifetime. Yet, historically, embodied carbon has been overlooked for reasons such as a high focus on operational carbon, a lack of awareness and regulation around the subject, fragmented supply chains, and cost being the main driving factor of projects.

However, within the lighting industry and wider construction industry there has been a growing recognition of the importance of embodied carbon in achieving sustainability goals. Efforts to raise awareness, develop standardised assessment methods, and implement policies and incentives to address embodied carbon are helping to shift the industry toward more sustainable practices.

The embodied carbon journey

Our approach to embodied carbon

Working closely with its material suppliers, Thorlux is determined to reduce the embodied carbon of its luminaires, re-localising material sources and eliminating carbon-heavy transport methods like air freight. Guidance, such as the CIBSE/SLL TM65 frame work, is being consulted to estimate the embodied carbon contributions that arise from Thorlux luminaires.

Reducing our embodied carbon

Thorlux is taking steps to reduce embodied carbon in its products, including using low-carbon alternative materials - either direct replacements (i.e. low-carbon versions of the same material) or completely different materials such as wood or bio plastics.

By using life cycle analysis assessment tools, such as CIBSE’s TM65 methodology, embodied carbon benchmarking and accounting is carried out to assess either the complete luminaire, or certain components used.

Many of Thorlux Lighting's operational improvements have already helped to reduce embodied carbon. These include switching to 100% renewable energy and decreasing reliance on gas. Thorlux will continue investigating in more energy-efficient manufacturing methods and machinery, with further energy conservation projects due in 2025 and beyond.